India's Leading Lead Supply Company!

About Opterro

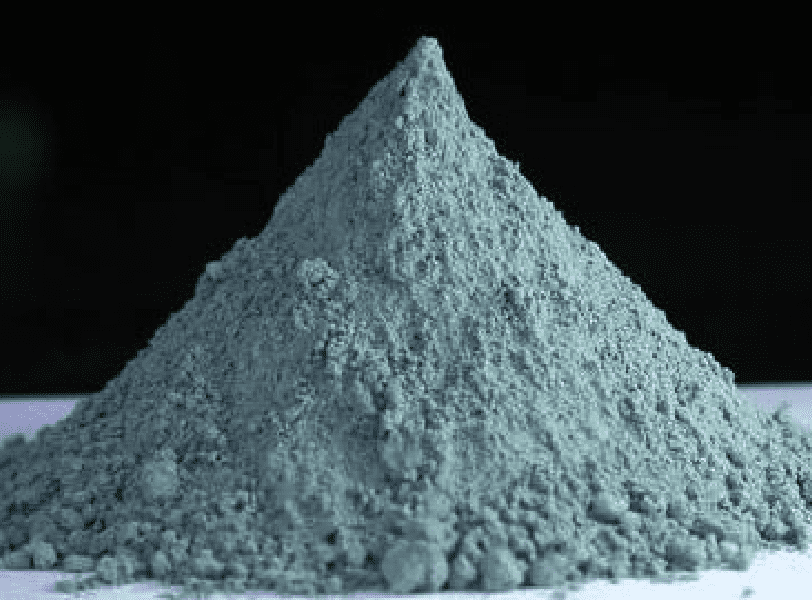

Opterro, a trusted name in metal smelting and refining, brings 12+ years of industry excellence. As we embrace this new chapter, we mark a milestone in innovation and commitment. Our expertise remains unwavering, delivering exceptional value and setting new benchmarks. Together, we move forward with confidence and purpose.

+12 +Years of Experience

Opterro is a renowned and trusted name in the field of metal smelting and refining.

+Advantages of Opterro:

By leveraging advanced technologies and a commitment to innovation, Opterro ensures optimized process efficiency, reduced costs, and minimized environmental impact.